Main Configurations of Parts Former

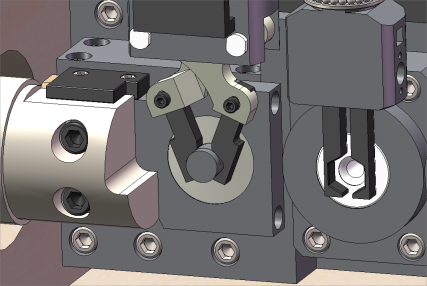

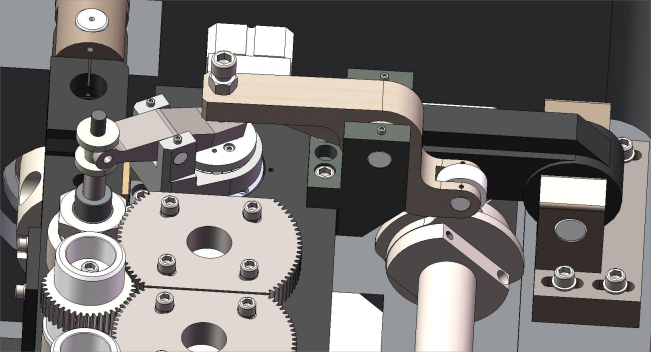

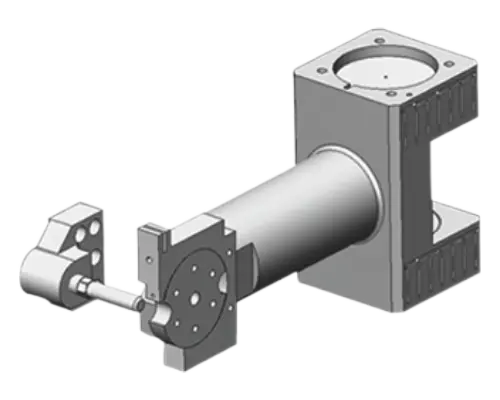

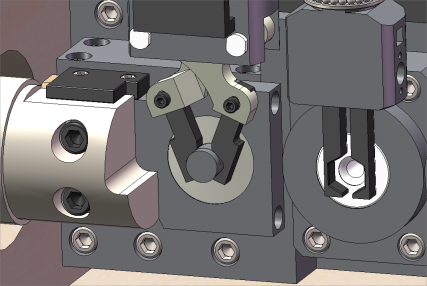

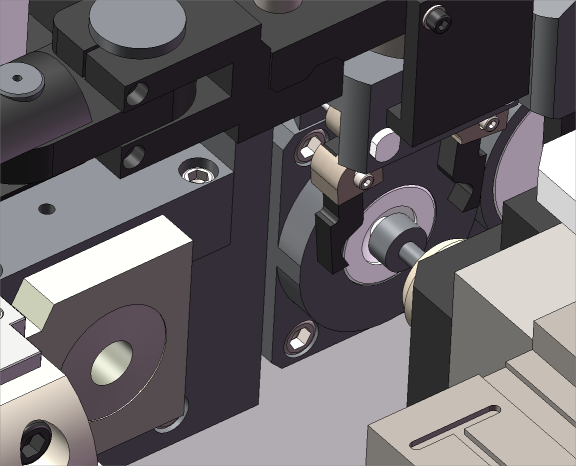

Configuration ① Circular cutter and independent clamp frame material-clamping mechanism:

The cutting adopts an integral circular cutting design. When the wire rod is cut, the parallelism is controlled, making the cross-section of the wire rod flatter, and greatly improving the qualified rate of the material.

The independent clamp frame drive structure works in conjunction with the circular cutter for material cutting. The rear thimble pushes the material from the cutting die into the clamp, and then transports it to the next workstation.

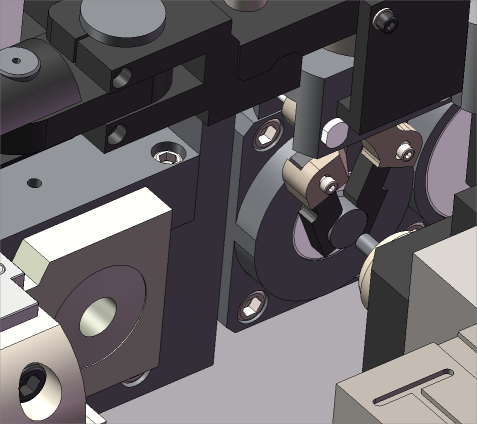

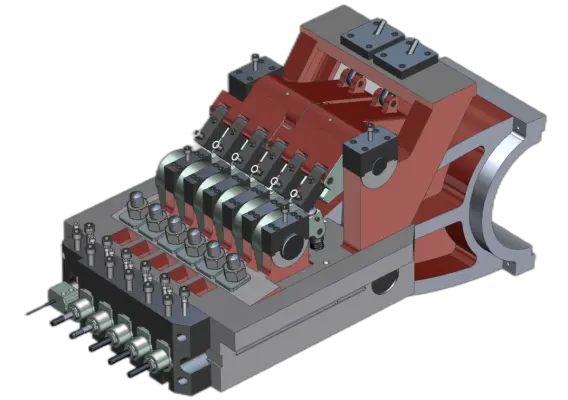

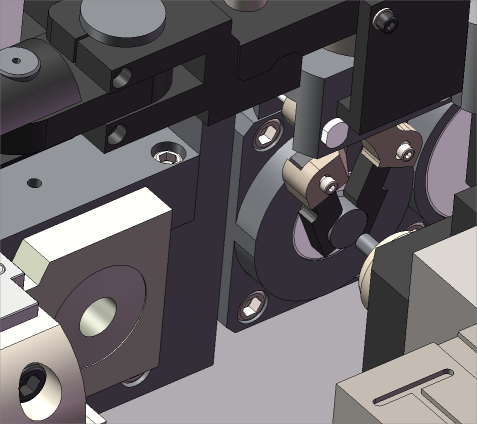

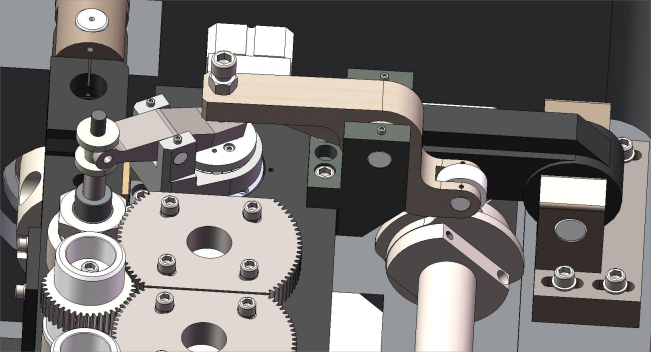

Configuration ② Clamp opening and ball-pressing mechanism:

The clamp shaft adopts an independent clamp-opening structure. The clamp freely expands, contracts, opens, and clamps materials driven by a cam. It can achieve clamp-opening and ball - pressing, meeting the needs of forming various special-shaped parts.

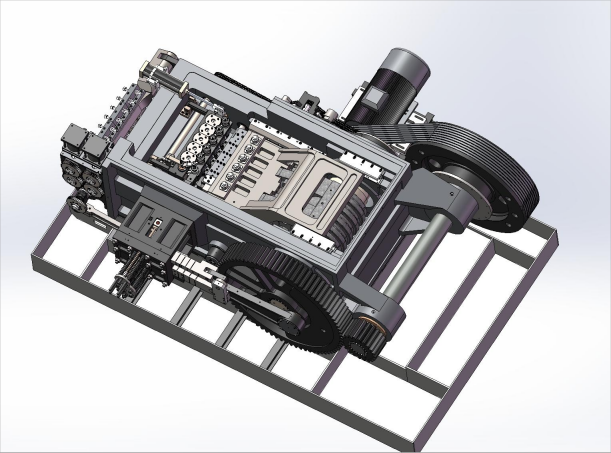

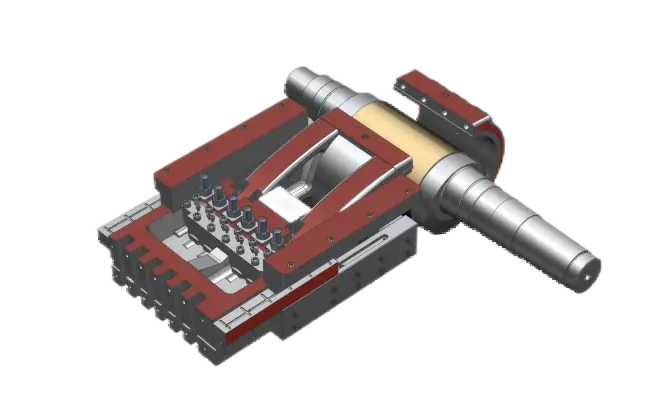

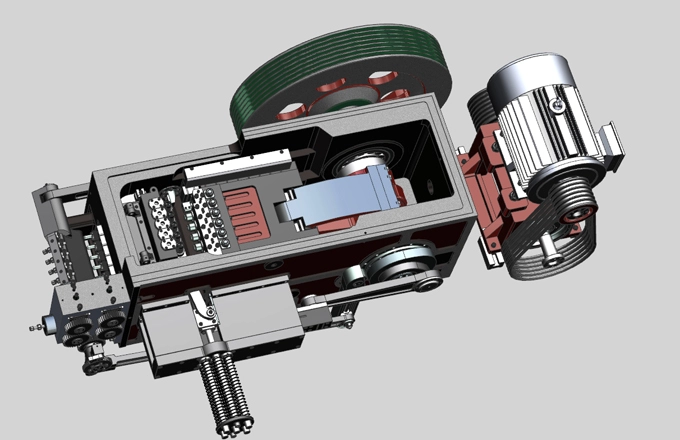

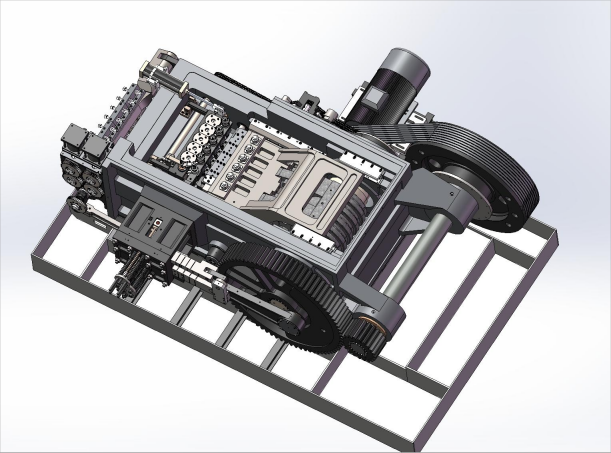

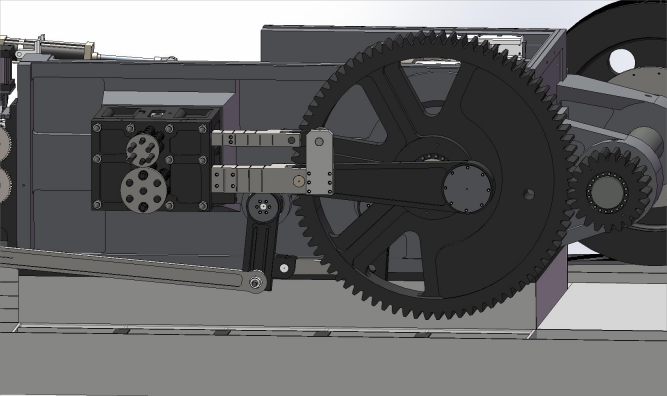

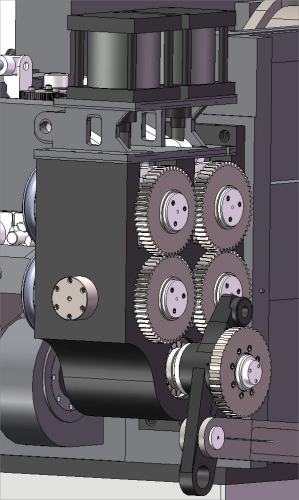

Configuration ③ The machine body is equipped with a back shaft, main flywheel and auxiliary flywheel.

It adopts a rigid transmission design with large-module gears, which significantly improves the stability of power transmission and transmission efficiency. Gears transmit torque, resulting in less loss compared to the belt drive of traditional cold heading machines.

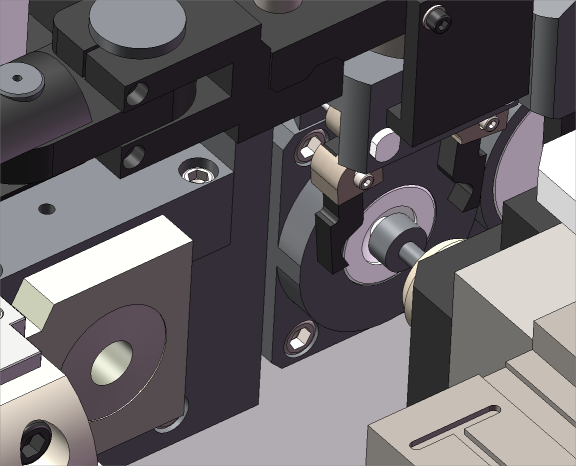

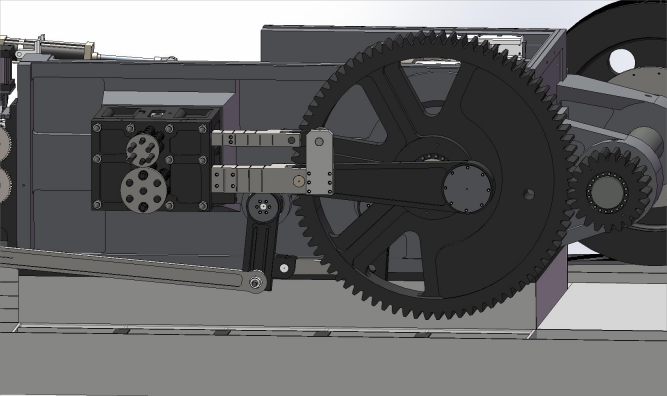

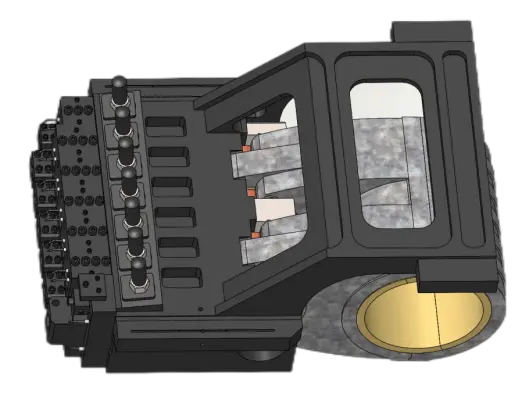

Configuration ④ Integrated shear box, driven by double S-plates

The shearing mechanism adopts a double-S-plate drive design with an integrated shear box. One S-plate drives the shear tool rod to perform reciprocating material-cutting movements, and the other S-plate drives the clamp frame pull rod to perform reciprocating material-clamping movements. This enables the actions of the cutter and the clamp frame to be completely independent yet coordinated.

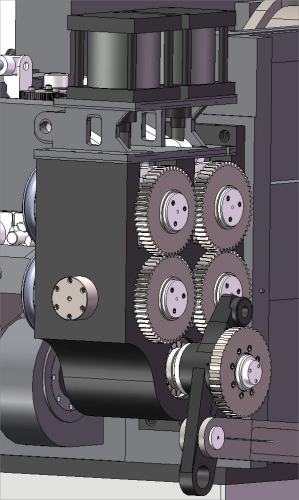

Configuration ⑤ Feeding box cylinder material-pressing mechanism

The feeding box is equipped with a cylinder material-pressing system, which makes it more labor-saving and convenient when adjusting the wire - pressing wheels. The pressure is adjustable to prevent the wire rod from being flattened due to excessive pressure.

(1).webp)

English

English