- Home

-

Cold Headers

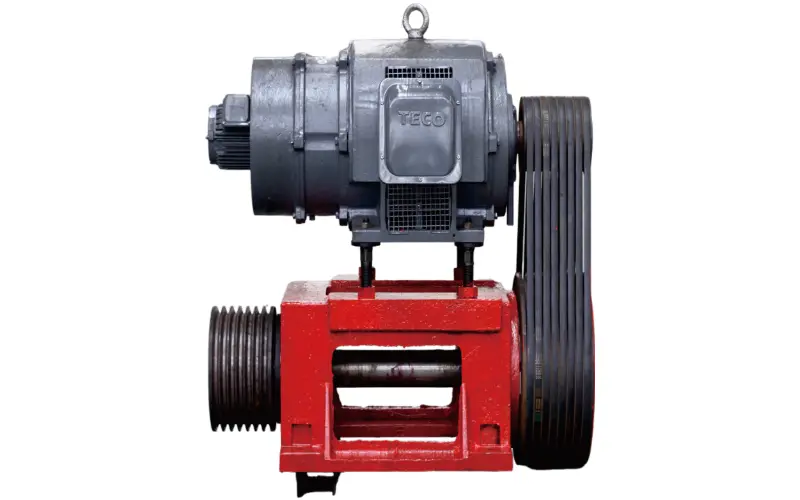

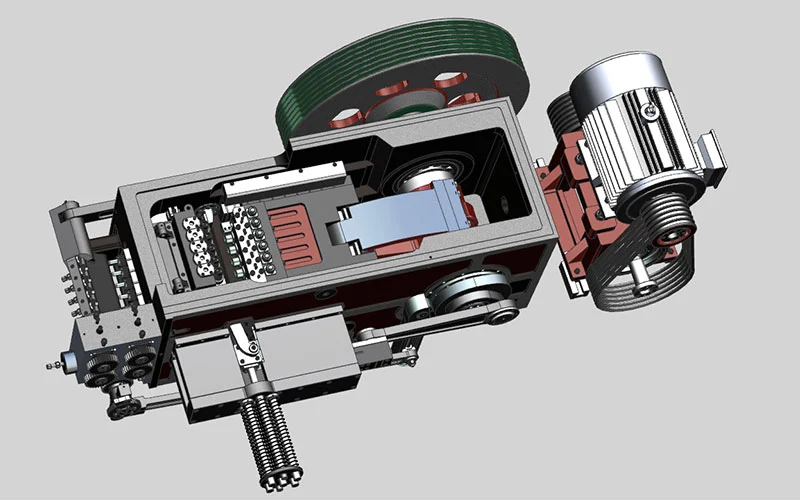

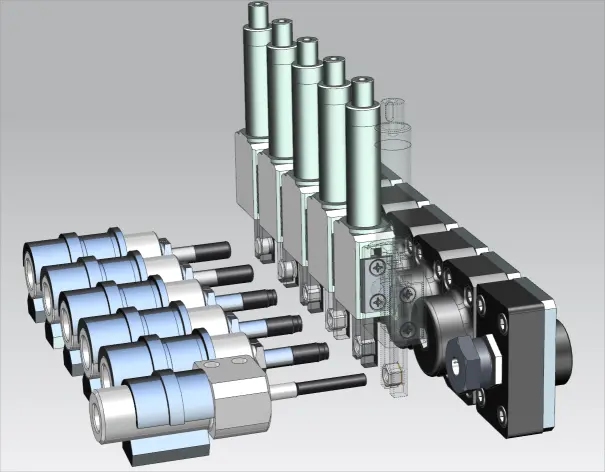

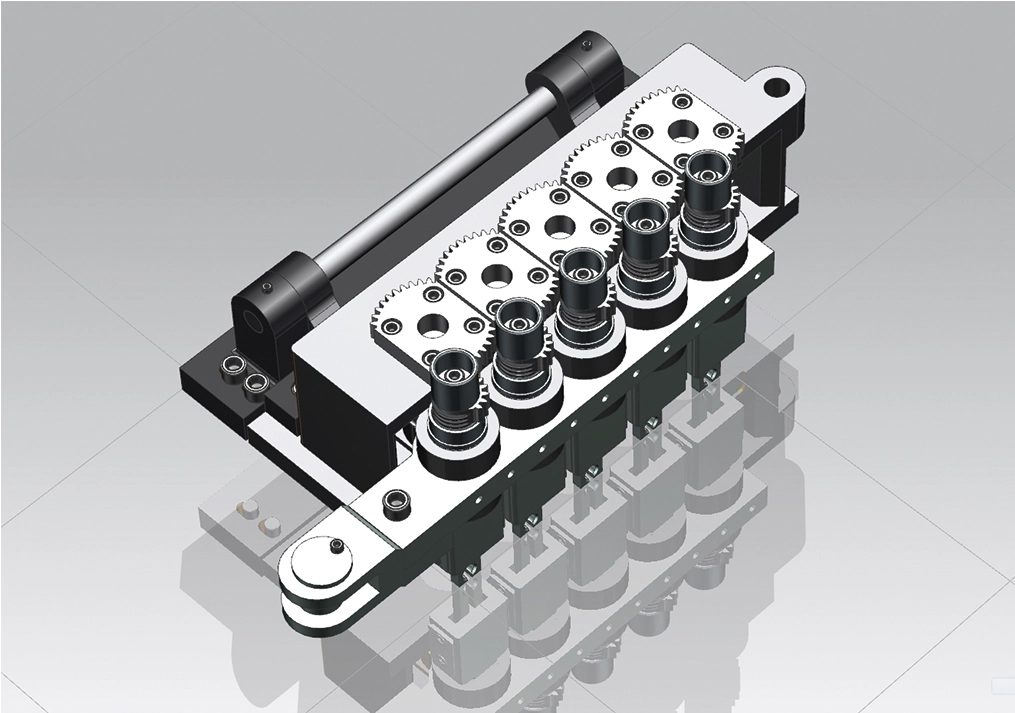

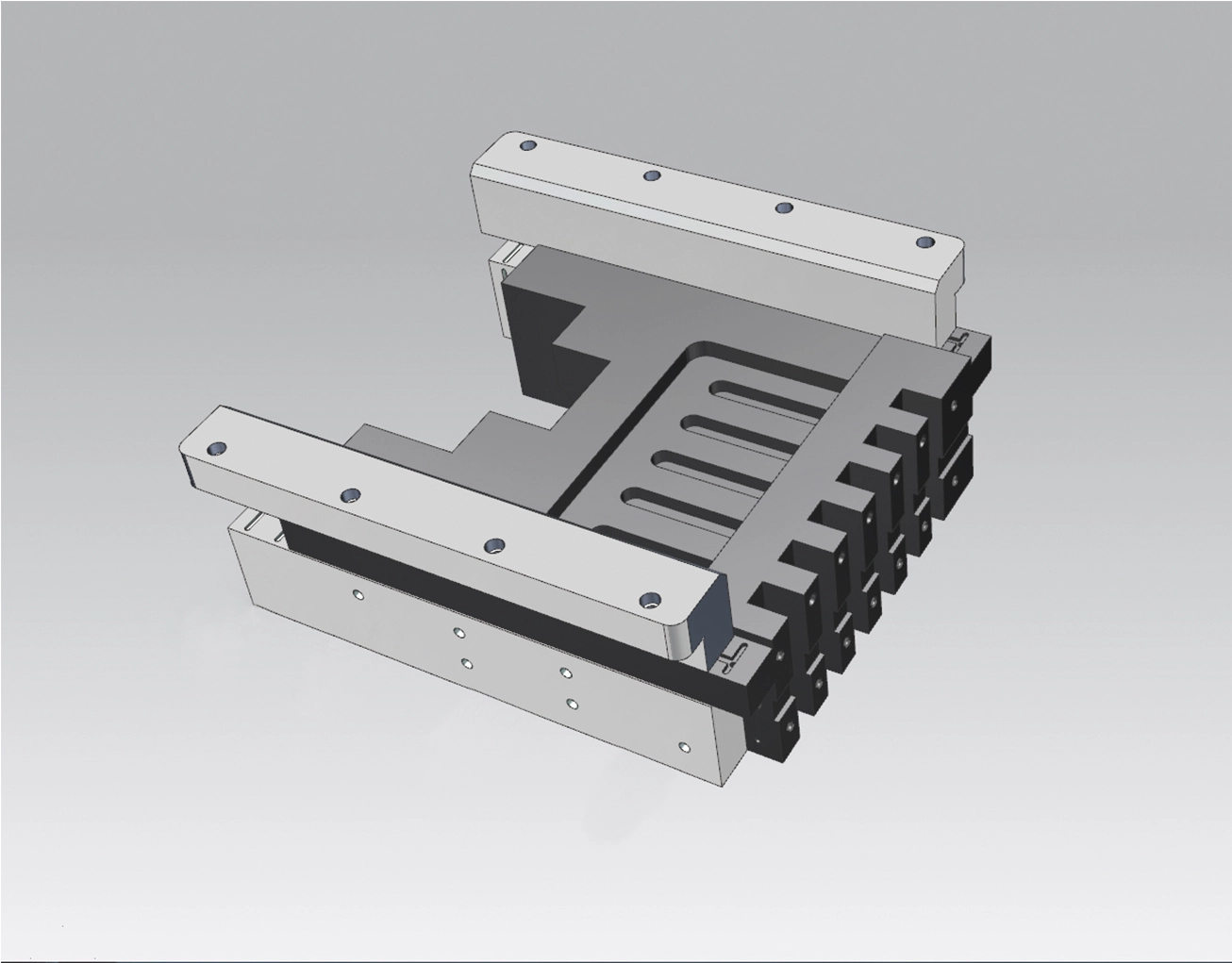

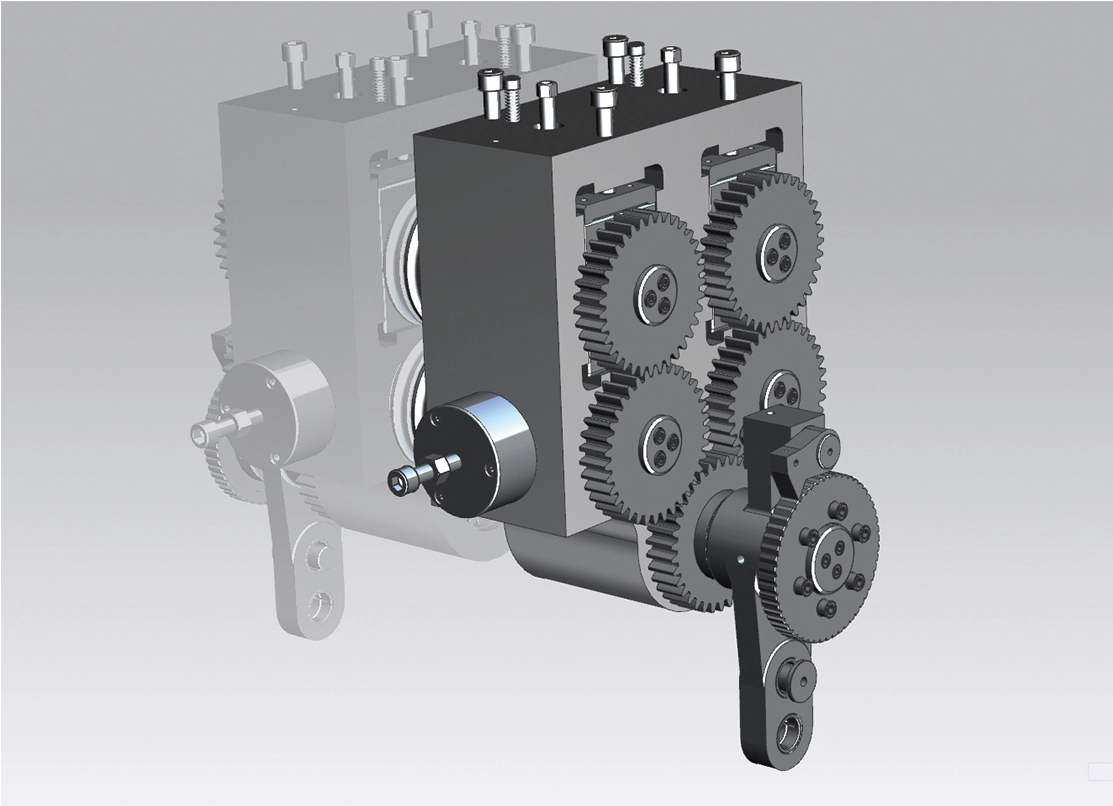

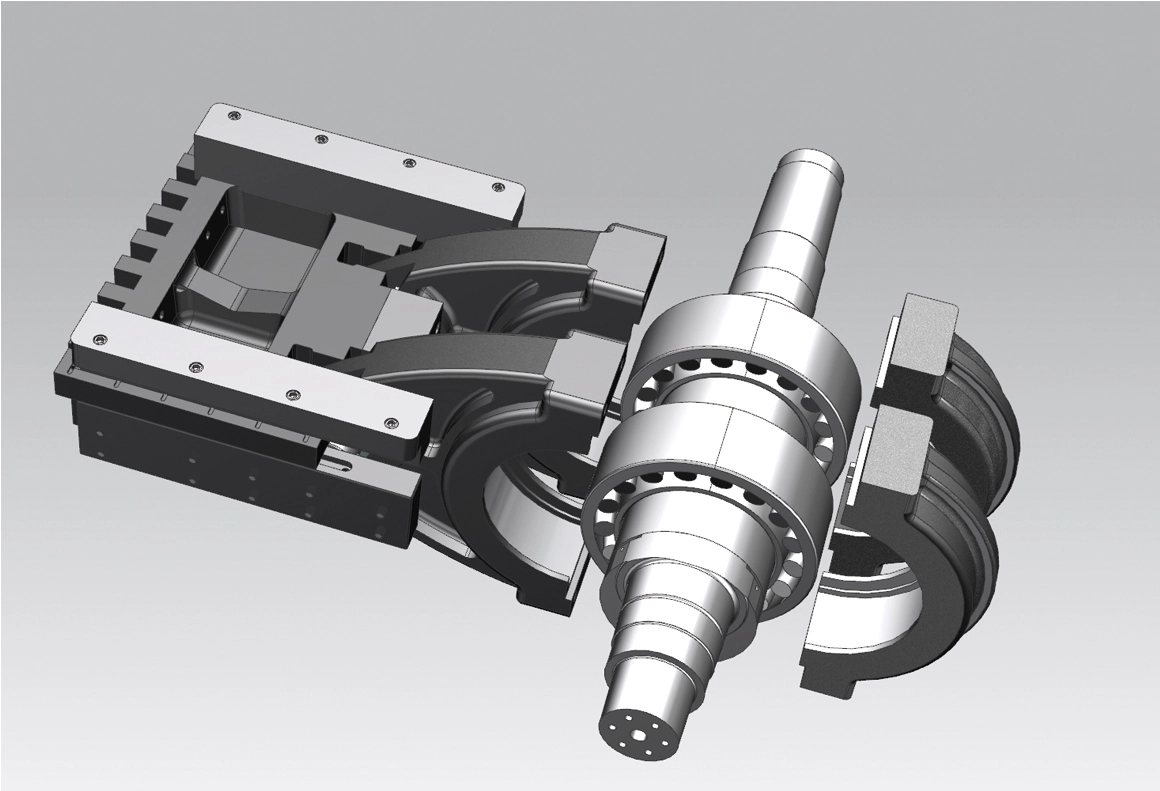

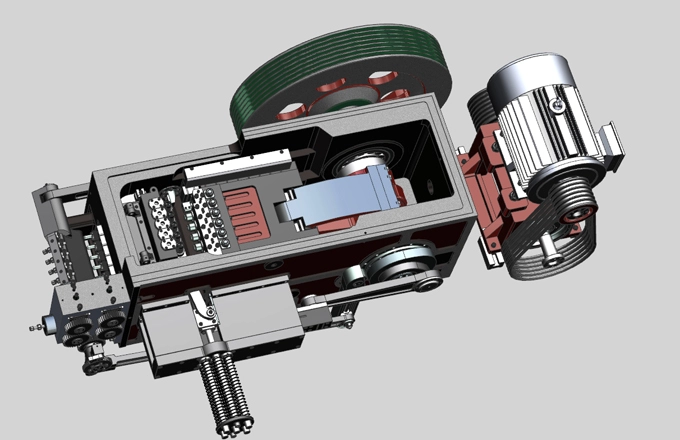

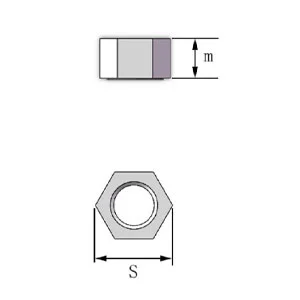

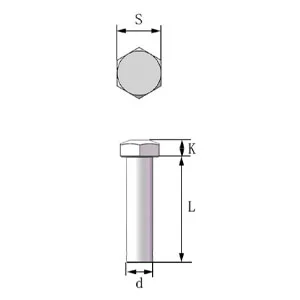

Nut Cold Heading MachineThe nut cold heading machine can meet various nut requirements. It can produce cold-headed nuts with a width across flats (S) of 9-58mm and a length (m) of 10-70mm, at a production speed of 50-300 pieces per minute.Bolt Cold Heading MachineThe bolt cold heading machine can meet various bolt requirements. It can produce cold-headed bolts with a head width across flats (S) of 9-58mm, a tail diameter (d) of 6-38mm, and a total length (S+L) of 6-500mm, at a production speed of 50-300 pieces per minute.Parts FormerParts former can meet the requirements for various non-ferrous metal products suitable for cold heading. The maximum outer diameter (S) of the products can reach 8-70mm, and the length (H) can reach 8-500mm, with a production speed of 50-300 pieces per minute.

- Application

- Company

- Blog

(1).webp)

English

English

.webp)