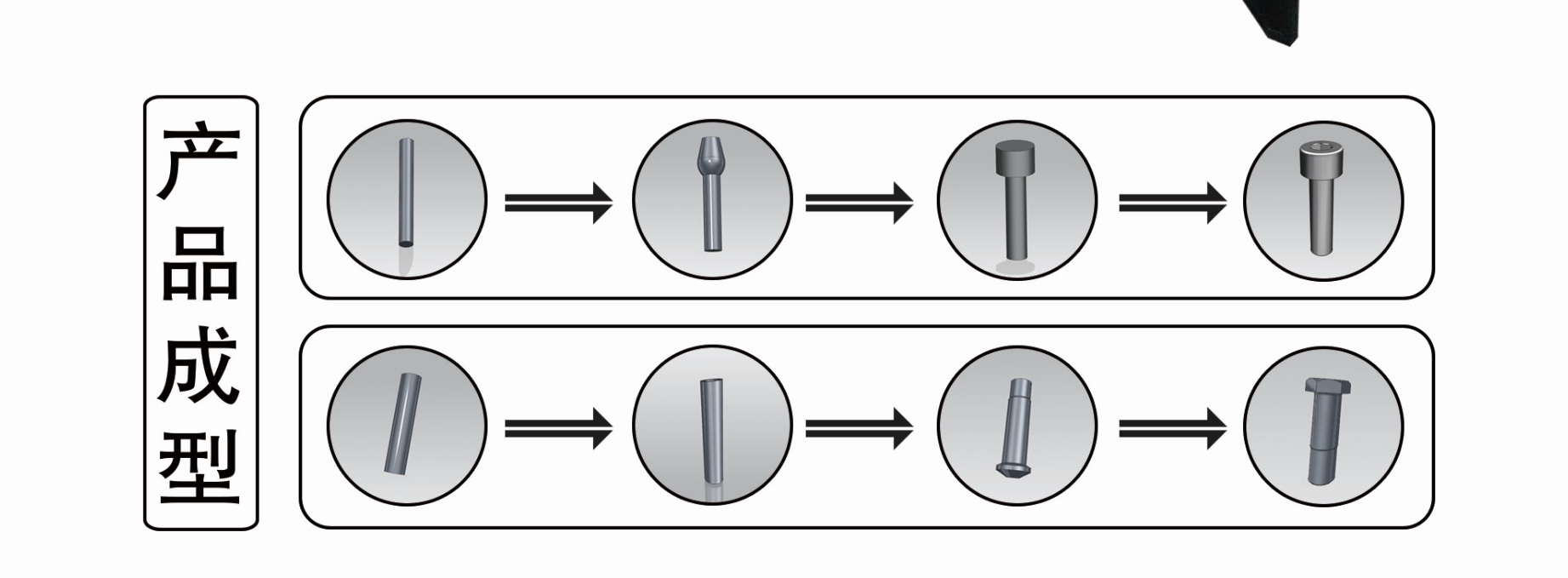

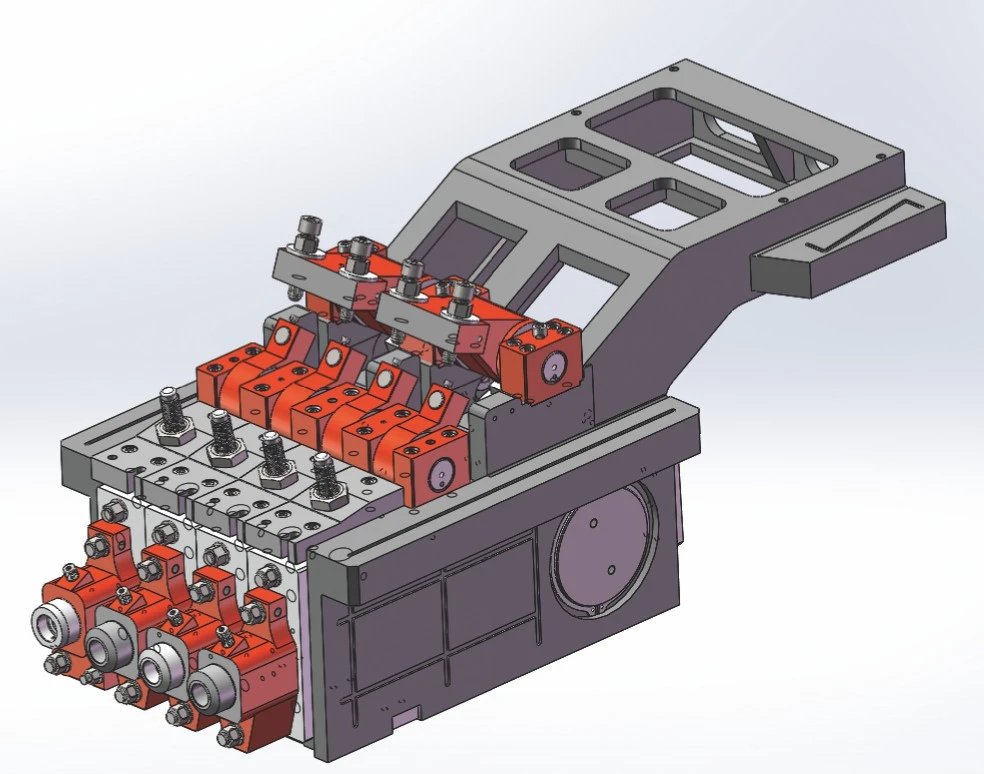

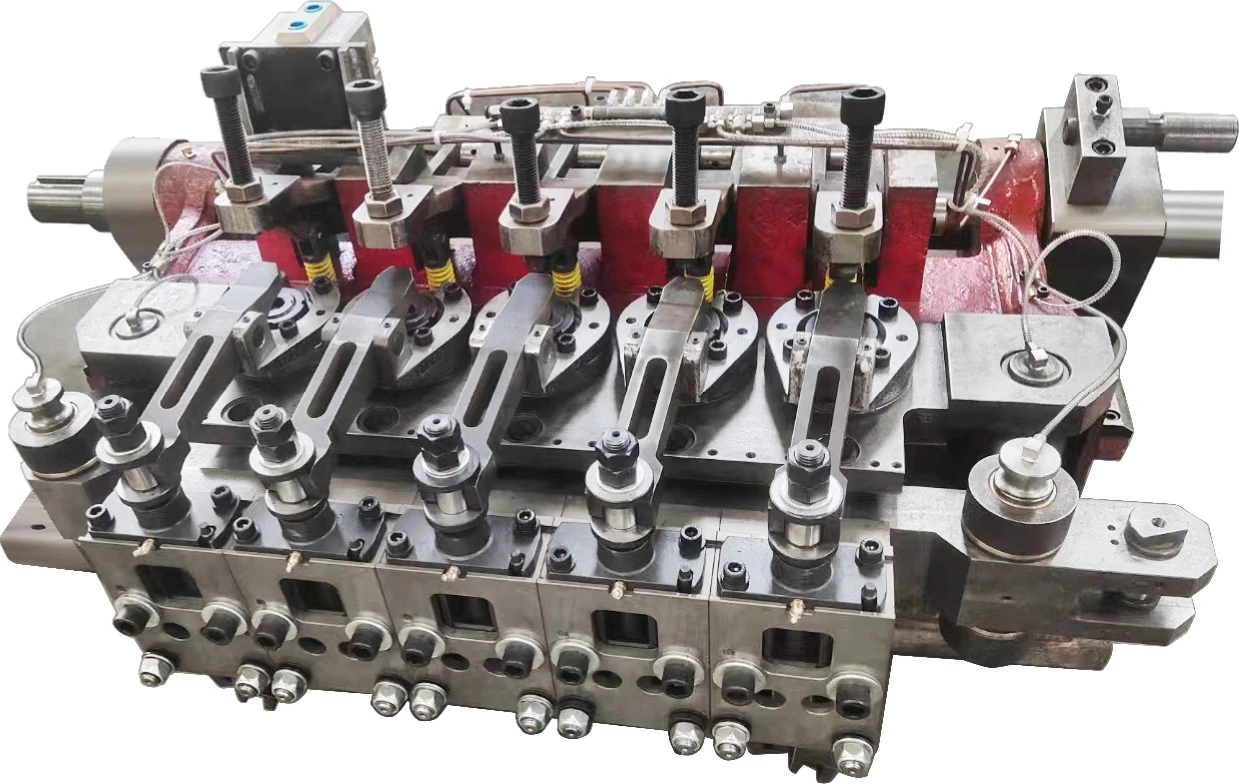

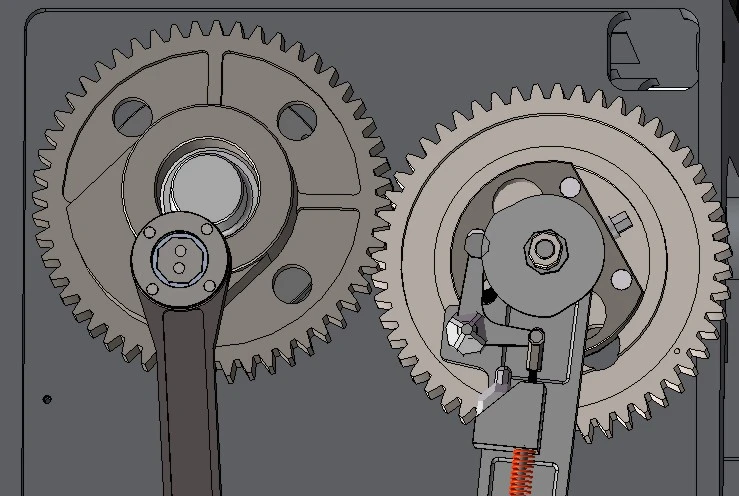

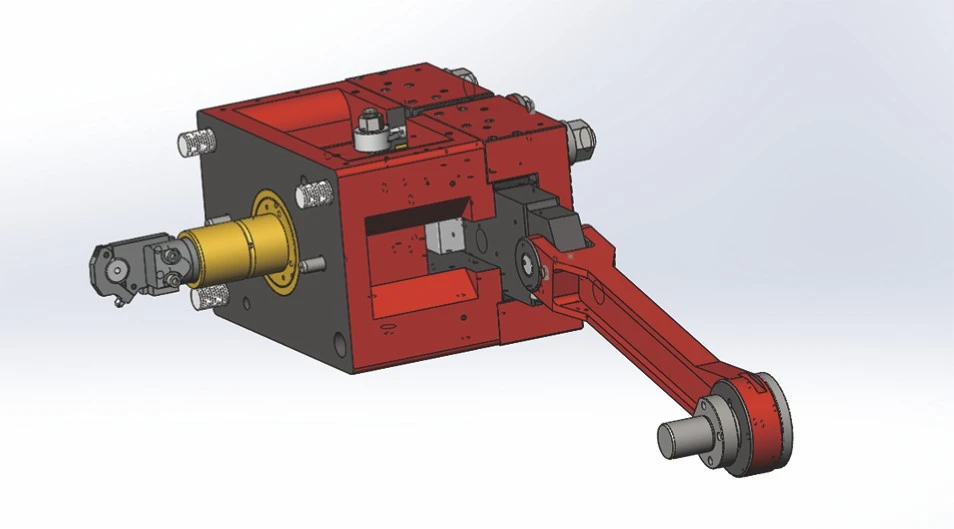

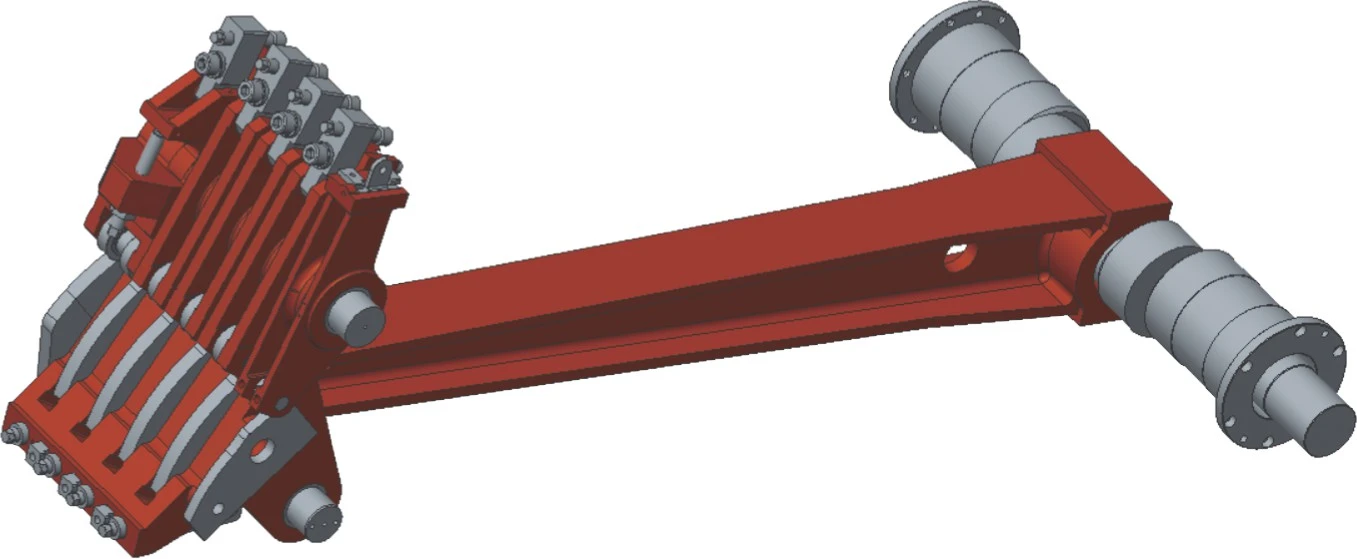

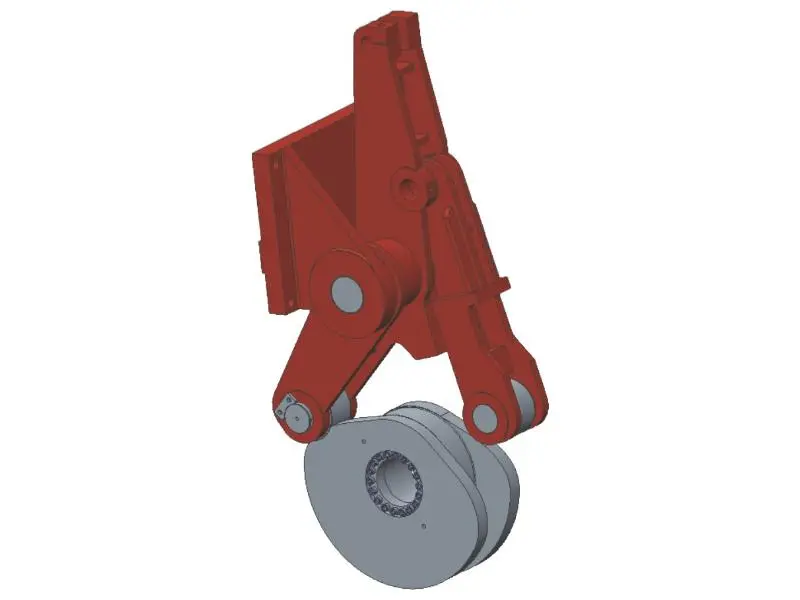

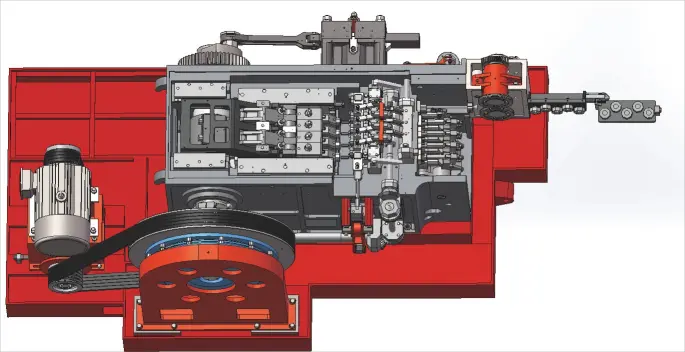

Setting up a Three Die Three Blow Bolt Forming Machine involves several critical steps to ensure accurate and efficient operation. First, load the appropriate wire or rod stock into the wire feeder. Next, adjust the three heading dies and punches to the desired dimensions, ensuring they are properly aligned and secured. Configure the machine’s settings, such as stroke length, feed rate, and blow sequence, to match the specific bolt size and shape you intend to produce. Detailed setup procedures, including safety checks and calibration steps, are usually provided in the machine’s manual. It’s essential to follow these guidelines closely to achieve optimal performance and product quality.

(1).webp)

English

English.webp)

.webp)

.webp)

.webp)