In the automotive industry, fasteners are used to connect various parts of a car, from the engine to the chassis and the body structure. Although fasteners are small, they are not insignificant. On the contrary, fasteners play a key role.

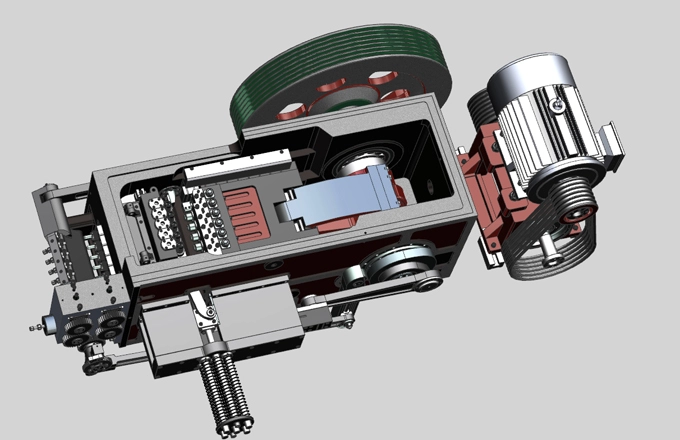

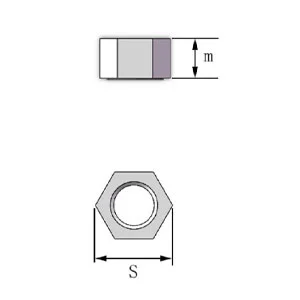

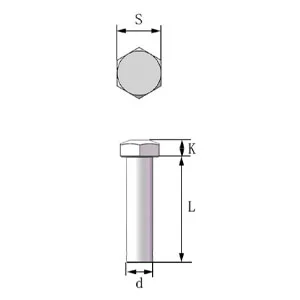

Special fasteners are used in engines, transmissions and suspensions. They must be able to bear huge weights, withstand high and low temperatures, corrosion, and withstand extreme conditions without failure. The precision and durability of the products are crucial. The cold heading process can produce fasteners with enhanced mechanical properties that can withstand high stress and extreme temperatures.

In addition to ensuring the stability and safety of the car during driving, the application of fasteners in the car interior must also take into account the aesthetics.

At the same time, it is very important to use lightweight fasteners. Reducing the weight of the vehicle by 10% can improve fuel economy by 6-8%, and changing the geometry of the fasteners can reduce the total weight by up to 35%.

Because fasteners affect the life, durability and safety of the vehicle, we are equipped with automated equipment and sophisticated measurement tools to achieve high precision and consistency, ensuring that each part meets the most stringent quality standards to optimize vehicle performance.

(1).webp)

English

English