There are many classification standards for aviation fasteners.

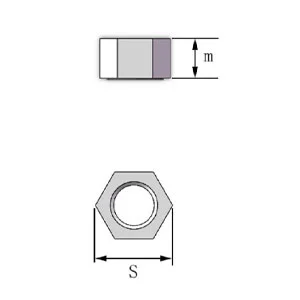

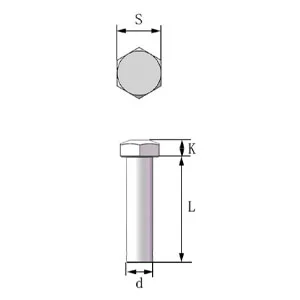

According to whether the fasteners are removable, they are divided into removable fasteners and permanent fasteners. Removable fasteners include bolts, screws and nuts; permanent fasteners include high-lock nuts, ordinary rivets, etc.;

According to product type, they are divided into bolts (screws), nuts, single-sided fasteners, special fasteners, etc.;

According to the materials used for fasteners, they are divided into carbon structural steel fasteners, alloy structural steel fasteners, stainless steel fasteners, high-temperature alloy fasteners, aluminum alloy fasteners, titanium alloy fasteners, titanium-niobium alloy fasteners and non-metallic fasteners, etc.;

According to the differences in assembly operation requirements, they are divided into single-sided fasteners and double-sided fasteners; according to the differences in the nature of the working load, fasteners are divided into two types: tensile type and shear type.

When selecting the material of aerospace fasteners, specific strength, fatigue resistance, corrosion resistance, rigidity, brittleness, compatibility, heat resistance and other properties are important indicators. Generally speaking, in the high-temperature parts of the engine, the fastener materials are mostly high-temperature alloys, such as GH2132, GH4738, GH4169, etc.; in the low-temperature parts, the fastener materials are mainly stainless steel and alloy steel, such as 1Cr11Ni2W2Mo V, 40Cr Ni Mo, etc.; if there is a need to reduce weight, titanium alloy fasteners can be selected in a targeted manner.

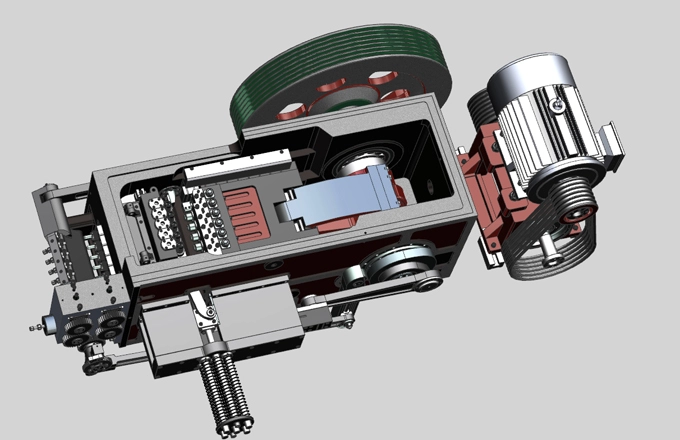

Aerospace fasteners are mainly titanium alloy fasteners, and their forming is crucial. The industry uses semi-hot or cold forming or cutting methods. This industry has extremely strict standards, and our equipment is innovative for this purpose.

(1).webp)

English

English